Menu

- Products

- Activ Wall

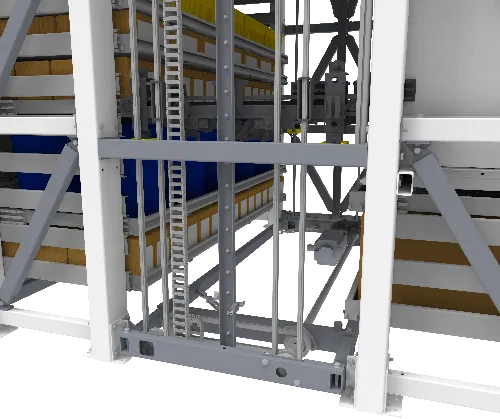

- Storage Systems

- Automotive Workbenches

- Casework

- Clean Rooms/Modular Buildings

- Foldable Furniture

- Labs and Pharmacies

- Mailrooms

- Mezzanines/Catwalks

- Seating

- Wire Cages/Guarding

- Workbenches/Workcenters

- Markets

- Services

- Resources

- About